| Specifications |

Range |

| Steel Thickness Range |

5MHz probe: 0.040 to 20″ (1.0 to 508mm); 10MHz probe: 0.030″ to 2″ (0.76mm to 50.8mm)

|

| Material velocity calibration range |

0.200 to 0.7362 in/μS (0.508 to 18.699mm/μS)

|

| Languages |

English, French, Spanish, Italian, Czech, German, Portuguese, Slovak, Finnish, and Hungarian

|

| Hold Mode |

Holds display to retain last thickness reading with reverse video display

|

| Freeze Mode |

Freezes display (ideal for high-temperature readings)

|

| Fast Min/Max Mode |

Displays Min or Max and actual thickness value at 20 measurements/sec

|

| Units |

Inches/Millimeters/Microseconds

|

| Alarms |

Audible beeping; illuminate flashing display and keypad; and vibration feedback

|

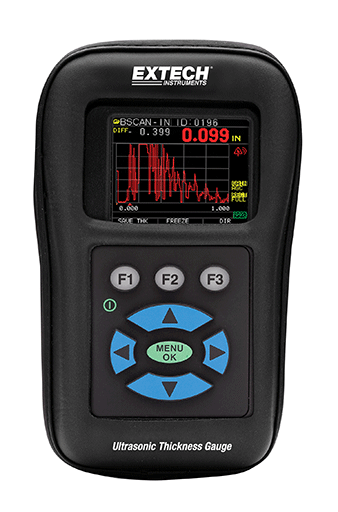

| Illuminating Keypad |

F1 = Red, F2 = Yellow, F3 = Green for easy, go/no-go testing

|

| Gain – Variable adjustment |

In 1dB steps from 20-90dB or Automatic Gain Control (AGC) for waveform

|

| B-Scan – Displays a cross-section of the test piece |

Displays a visual cross-section of the inspection area with no correlation to distance. B-Scan alarm colors consist of: Red = below minimum/above maximum; Yellow = Caution; and Green = Good.

|

| Echo to Echo |

Measure the metal thickness only (paint & coatings do not affect base material thickness value)

|

| Differential Mode |

Displays the difference from the actual thickness measurement and a user-entered reference value

|

| Velocity Mode |

Displays acoustic sound speed to measure the thickness of unknown materials

|

| Datalogger |

Stores 50k readings (expandable to 100k) and 5,000 waveforms; file names up to 20 characters long; and the included Extech XPorter software extracts .csv data files that can be opened for viewing in MS Excel, Notepad, or Wordpad. File compare & grid review

|

| Range |

Adjustment of manual range control or auto-zoom tracking to center echoes independent of the selected range

|

| Rectification Modes |

RF, Half Wave Positive, Half Wave Negative and Full Wave Rectification

|

| Live Waveform (A-Scan) |

Full adjustments for gain in 1dB step or AGC, main bang blank, blank after first received echo, the range including zoom auto-tracking to center echoes independent of material and rectification

|

| Battery Life |

8 to 14hrs (depends on operating conditions)

|